كيف توفر لك 6 قطع من مضخة المياه المصنوعة من الحديد الزهر أموالك على المدى الطويل

مرحباً بكم في مدونتي!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

جدول المحتويات

مقدمة

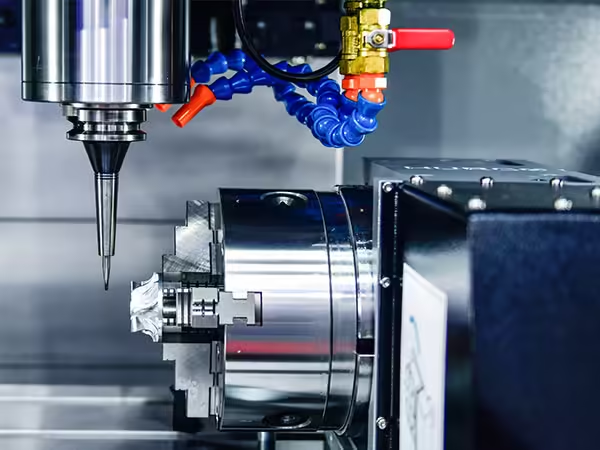

In industrial and commercial water systems, the choice of pump components significantly impacts operational costs and system longevity. Among various material options, cast iron water pump parts stand out for their exceptional durability, cost-effectiveness, and reliable performance. This article examines six critical cast iron components that contribute to substantial long-term savings by reducing maintenance requirements, extending equipment lifespan, and improving energy efficiency.

We will explore these components in detail, highlighting their specific benefits and cost-saving advantages. Additionally, we will reference two premium cast iron water pump parts manufactured by Shanghai Leierwo Industry & Trade Co., Ltd. – the cast iron pump housing and slurry pump impeller – to demonstrate how precision engineering and high-quality materials translate into financial benefits for end users.

NO 1. Cast Iron Pump Housing: The Structural Backbone

The cast iron pump housing stands as one of the most critical cast iron water pump parts, serving as the primary protective enclosure for internal pump mechanisms. This essential component plays a crucial role in maintaining system integrity across various operating conditions in water pump systems.

Durability and Cost Savings

Among all cast iron water pump parts, the housing offers superior resistance to mechanical stress and corrosion compared to alternative materials. The robust construction of these cast iron components provides several financial advantages:

Extended service life of cast iron water pump parts reduces replacement frequency Superior corrosion resistance in cast iron components minimizes maintenance requirements High structural integrity prevents catastrophic failures in water pump systems Thermal stability maintains dimensional accuracy in cast iron water pump parts under temperature fluctuations

Shanghai Leierwo’s precision-cast pump housings represent premium examples of cast iron water pump parts, incorporating advanced metallurgical properties that enhance these benefits, ensuring optimal performance in demanding water pump applications.

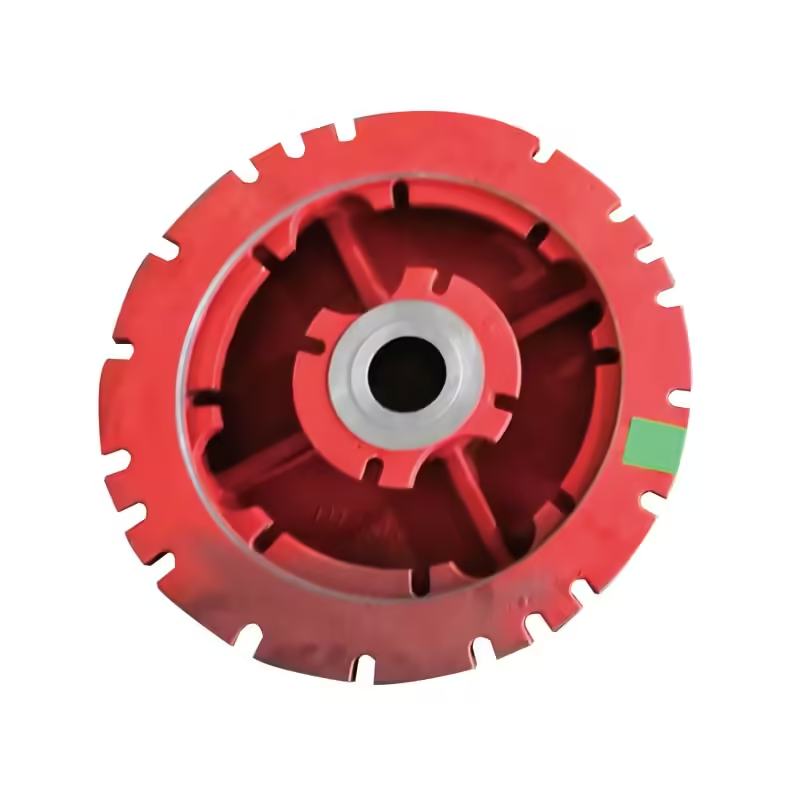

NO 2. Slurry Pump Impeller: Engineered for Abrasive Service

Slurry pump impellers crafted from high-grade cast iron demonstrate why they’re among the most valuable cast iron water pump parts when handling abrasive or corrosive fluids. These specialized components are particularly crucial in mining, wastewater treatment, and industrial processing applications where water pumps face extreme conditions.

Operational Efficiency and Financial Benefits

The specialized design of these cast iron water pump parts delivers measurable cost reductions:

Optimized hydraulic geometry in cast iron impellers reduces energy consumption by 8-12% Enhanced wear resistance extends maintenance intervals for these water pump parts by 30-50% Precision-balanced construction minimizes vibration-related wear in cast iron components Customizable designs accommodate specific application requirements for water pumps

Leierwo’s slurry impellers, as premium cast iron water pump parts, undergo rigorous quality control including material composition analysis, mechanical performance testing, dimensional inspection, and non-destructive testing to ensure reliability in water pump systems. These cast iron components are engineered to withstand the most challenging conditions while maintaining efficiency in water pump operations.

The manufacturing process for these cast iron water pump parts involves advanced foundry techniques that optimize the material properties specifically for water pump applications. This attention to detail results in cast iron components that outperform alternatives in both durability and operational efficiency for water pump systems.ensuring consistent performance in challenging environments.

NO 3. Wear Plates: Cost-Effective Protection

Wear plates function as sacrificial components that shield more expensive pump elements from abrasive damage. These cast iron parts represent a strategic investment in system protection.

Maintenance Cost Reduction

The implementation of high-quality wear plates generates multiple financial benefits:

- 40-60% reduction in major component replacement costs

- Simplified maintenance procedures decrease labor expenses

- Interchangeable design allows selective replacement of worn sections

- Consistent performance across temperature ranges

NO 4. Shaft Sleeves: Preserving Critical Components

Cast iron shaft sleeves provide essential protection for pump shafts, preventing premature wear and corrosion in this vital component.

Long-Term Asset Protection

The financial advantages of premium shaft sleeves include:

- 70-80% reduction in shaft replacement frequency

- Corrosion-resistant surfaces maintain sealing integrity

- Precision-machined surfaces ensure proper alignment

- Cost-effective alternative to complete shaft assemblies

NO 5. Volute Casings: Optimizing Hydraulic Efficiency

The volute casing’s design significantly impacts pump efficiency and energy consumption. Cast iron construction ensures durability while maintaining precise hydraulic characteristics.

Energy Cost Savings

Well-engineered volute casings contribute to:

- 5-15% improvement in overall pump efficiency

- Reduced cavitation potential extends component life

- Stable pressure conversion minimizes energy losses

- Dimensional stability maintains performance over time

NO 6. Bearing Housings: Ensuring Reliable Operation

Cast iron bearing housings provide critical support for rotating assemblies, directly influencing system reliability and maintenance costs.

Downtime Reduction

Superior bearing housings deliver:

- 50% longer bearing service life

- Vibration damping protects adjacent components

- Rigid construction maintains alignment precision

- Simplified maintenance access reduces service time

Performance Comparison of Key Components

| Component | Primary Benefit | Cost Impact | Service Life Improvement |

|---|---|---|---|

| Pump Housing | Structural integrity | 60% lower replacement costs | 2-3x longer |

| Slurry Impeller | Abrasion resistance | 35% energy savings | 50% longer |

| Wear Plates | Component protection | 75% lower repair costs | 3-4x longer |

| Shaft Sleeves | Shaft preservation | 80% fewer shaft replacements | 2x longer |

| Volute Casings | Hydraulic efficiency | 12% energy reduction | Consistent performance |

| Bearing Housings | Vibration control | 50% less downtime | 60% longer |

خاتمة

The strategic selection of cast iron water pump parts represents a sound financial decision for any operation requiring reliable fluid handling. The six components discussed – pump housing, slurry impeller, wear plates, shaft sleeves, volute casings, and bearing housings – each contribute uniquely to reducing operational expenses while enhancing system performance.

Shanghai Leierwo Industry & Trade Co., Ltd. specializes in manufacturing these critical components to the highest quality standards. Their expertise in precision casting ensures that each part delivers maximum value through extended service life, reduced maintenance requirements, and improved energy efficiency. By investing in premium cast iron water pump parts, operators can achieve significant long-term savings while maintaining consistent, reliable system performance.

الأسئلة الشائعة

What makes cast iron superior to other materials for pump components?

Cast iron offers an optimal balance of strength, corrosion resistance, and cost-effectiveness. Its excellent vibration damping characteristics and thermal stability make it particularly suitable for demanding pump applications.

How often should cast iron pump components be inspected in normal service?

For typical industrial applications, comprehensive inspections every 6-12 months are recommended. However, components handling abrasive fluids may require quarterly inspections to monitor wear patterns.

Can cast iron parts be customized for specific applications?

Yes, manufacturers like لييروو offer complete customization services, including dimensional modifications, material composition adjustments, and specialized surface treatments to meet unique operational requirements.

What industries benefit most from cast iron pump parts?

Mining, water treatment, chemical processing, power generation, and agricultural irrigation systems all benefit significantly from the durability and cost-efficiency of cast iron components.

How does proper component selection impact energy consumption?

Optimized cast iron components improve hydraulic efficiency, reduce friction losses, and minimize vibration – collectively contributing to energy savings of 5-20% depending on system design and operating conditions.

فئات المنتجات

- أجزاء الصمامات

- أجزاء مضخة المياه

- أجزاء صندوق المحمل

- أجزاء الصب بالقالب

- منتجات مضخات الفولاذ المقاوم للصدأ

- منتجات مضخات الحديد الزهر

- قطع غيار الصمامات لاستخدام السيارات

- قطع غيار السيارات

- أجزاء الصمامات للاستخدام المدني

- قطع غيار مضخة التفريغ KF