5 Key Advantages of Stainless Steel Casting Impeller

Willkommen auf meinem Blog!

Ich freue mich sehr, dass du hier bist! Bevor wir uns in die Inhalte vertiefen, würde ich mich freuen, wenn du mir auf meinen Social-Media-Plattformen folgst. Dort teile ich zusätzliche Einblicke, vernetze mich mit unserer großartigen Community und halte dich über die neuesten Nachrichten auf dem Laufenden. So bleibst du in Verbindung:

📘 Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Lassen Sie uns gemeinsam auf diese Reise gehen! Ich hoffe, Sie finden die Inhalte hier nicht nur aufschlussreich, sondern auch inspirierend und wertvoll. Los geht‘s!

Inhaltsverzeichnis

Einführung

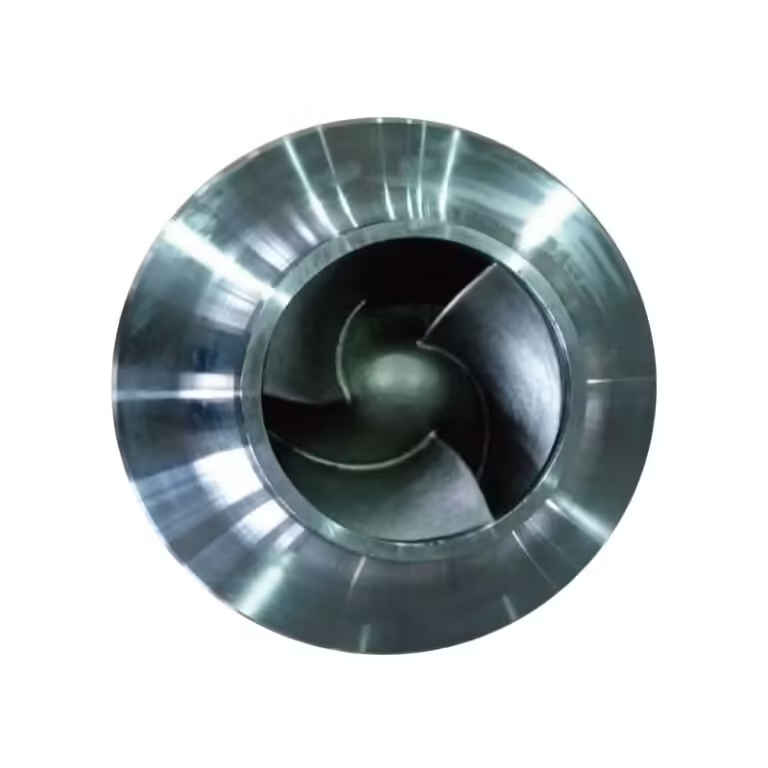

Stainless steel casting impellers are essential components in various industries, including manufacturing, automotive, and aerospace. These high-performance impellers play a crucial role in the movement of fluids and gases, making them a vital part of pumps, compressors, and other mechanical systems. Due to their durability, resistance to corrosion, and versatility, stainless steel casting impellers are often considered the best choice for critical applications.

In this article, we’ll explore the 5 key advantages of stainless steel casting impellers that make them a preferred option across industries. By the end, you’ll understand why this material is so highly valued and how it can impact the performance of your equipment.

NO 1. Durability and Longevity

Stainless steel casting impellers stand out in demanding industries due to their unmatched durability and long service life. In many industrial systems, impellers must operate continuously in aggressive environments, where factors like mechanical stress, thermal expansion, and fluid turbulence can significantly wear down materials. Fortunately, the unique metallurgical properties of stainless steel offer an effective solution.

The composition of stainless steel, often including elements like chromium, nickel, and molybdenum, significantly enhances the alloy’s structural integrity. This allows stainless steel casting impellers to retain their form and function even under high-pressure, high-temperature, and high-impact situations.

Benefits of Durability in Stainless Steel Casting Impellers

- Resistant to corrosion: By forming a passive oxide layer on the surface, stainless steel inherently protects itself from oxidation and corrosion. This makes it ideal for fluid systems that contain corrosive chemicals or operate in coastal environments.

- High strength: These impellers handle elevated torque and rotational speed without warping or breaking. This structural stability ensures reliable operation in pumps or turbines under dynamic loads.

- Extended service life: Stainless steel casting impellers have a proven record of withstanding years of continuous use with minimal performance degradation, making them a solid investment for long-term industrial reliability.

- Cost-effective over time: Though the initial investment may be higher, the reduced need for frequent repairs and replacements delivers substantial long-term savings.

NO 2. Excellent Corrosion Resistance

In many industrial sectors, exposure to moisture, salt, chemicals, and acidic substances is a common challenge. Equipment components must be able to resist deterioration caused by these conditions, and this is where stainless steel casting impellers excel.

Their superior corrosion resistance not only prolongs the component’s life but also preserves system integrity by minimizing the risk of contaminants leaching into fluids, especially in sensitive industries like food processing and pharmaceuticals.

How Corrosion Resistance Enhances Impeller Performance

- Ideal for wet environments: Water treatment plants, desalination facilities, and marine propulsion systems all benefit from stainless steel impellers that can operate without corrosion-related issues, even when submerged continuously.

- Resistant to chemicals: Impellers made from stainless steel can process acidic, alkaline, or otherwise reactive fluids without losing strength or shape. This capability is crucial in chemical reactors and mixing tanks.

- Less maintenance: Corrosion leads to pitting, scaling, and blockages. Stainless steel casting impellers prevent these problems, reducing the need for manual cleaning, surface treatment, and downtime for part replacement.

- Improved hygiene: In sectors requiring strict hygiene control, such as dairy, beverage, and biopharmaceutical industries, the non-reactive nature of stainless steel helps maintain sanitary standards.

NO 3. Superior Strength and Performance

The operational performance of an impeller is directly influenced by the strength of its material. Stainless steel casting impellers are engineered to maintain precise tolerances and deliver optimal performance under high-stress conditions. Their excellent tensile strength and fatigue resistance allow them to perform consistently across a range of applications.

This mechanical robustness enables them to handle dynamic forces generated by rotating parts, fluctuating pressures, and rapid fluid acceleration without deformation or performance loss.

Enhanced Strength for High-Pressure Applications

- High tensile strength: Stainless steel impellers can manage extreme centrifugal forces and pressure spikes, especially in heavy-duty industrial pumps or aviation applications.

- Consistent performance: The structural stability of stainless steel ensures minimal variation in performance, even under continuous or high-speed usage, which is vital for maintaining process efficiency.

- Smooth operation: The material’s rigidity minimizes vibration and mechanical noise, ensuring stable operation with reduced wear on surrounding components like bearings and seals.

- Resistance to fatigue: Under cyclic loading conditions, stainless steel impellers are less likely to develop micro-cracks or structural weaknesses over time.

NO 4. Resistance to Wear and Tear

Mechanical erosion is a leading cause of component failure in rotating equipment. Abrasive materials, cavitation, and fluid impact can gradually degrade impeller surfaces, leading to reduced efficiency and eventual breakdown. However, stainless steel casting impellers provide a significant advantage by offering exceptional resistance to physical wear.

Whether in slurry pumps, sewage systems, or industrial mixers, the hardness and toughness of stainless steel help maintain performance integrity in abrasive environments.

How Wear Resistance Affects Impeller Efficiency

- Less friction: The smooth surface finish of stainless steel casting impellers minimizes energy loss from friction, translating into more efficient fluid dynamics and reduced power consumption.

- Reduced downtime: Enhanced wear resistance lowers the risk of sudden failure or frequent repairs, allowing uninterrupted production schedules and lower maintenance costs.

- Longevity in challenging environments: Whether moving suspended solids or high-viscosity liquids, stainless steel impellers resist deformation and erosion, keeping pumps running at peak efficiency for extended periods.

- Surface treatments available: Additional surface treatments such as electropolishing or nitriding can further improve wear resistance, tailoring the impeller to specific use cases.

NO 5. Versatility in Applications

One of the standout features of stainless steel casting impellers is their adaptability. Their ability to meet a wide range of performance and safety standards makes them ideal for use in many industries. Whether the requirement is mechanical reliability, hygienic safety, or resistance to aggressive fluids, stainless steel impellers can be tailored to fit the need.

Different casting methods, such as investment casting and sand casting, allow for the production of impellers with intricate geometries and tight tolerances, ensuring precise customization for any industrial process.

Versatility of Stainless Steel Impellers in Various Industries

- Water treatment: These impellers are widely used in municipal and industrial water circulation systems, ensuring reliable operation in pumps and aerators.

- Pharmaceutical industry: Stainless steel impellers maintain purity and prevent contamination during fluid mixing and transfer processes.

- Oil and gas industry: In offshore and onshore environments, stainless steel casting impellers withstand exposure to hydrocarbons, saltwater, and high temperatures.

- Food and beverage: Their hygienic properties make them ideal for stirring, blending, and pumping liquids in food processing plants.

- Power generation: Impellers are used in turbine systems where high-speed fluid movement and long-term reliability are essential.

Comparison Table: Key Features of Stainless Steel Casting Impellers

| Feature | Importance Level | What to Look For |

|---|---|---|

| Haltbarkeit | Hoch | Ability to withstand harsh conditions for extended periods |

| Korrosionsbeständigkeit | Hoch | Resistance to rust and chemical degradation |

| Strength & Performance | Hoch | Ability to perform under high pressure and speed |

| Wear and Tear Resistance | Hoch | Minimizing the need for repairs or replacements |

| Versatility | Medium | Adaptability to a wide range of applications |

Abschluss

The advantages of stainless steel casting impellers are clear. Their durability, corrosion resistance, superior strength, wear resistance, and versatility make them an excellent choice for various industries. Whether you’re in the manufacturing, pharmaceutical, or chemical processing industries, these impellers offer long-lasting and reliable performance.

By choosing stainless steel casting impellers for your equipment, you’re ensuring the optimal performance and efficiency of your systems. The low maintenance and long service life, coupled with exceptional mechanical properties, make them a cost-effective and reliable solution.

Häufig gestellte Fragen

What makes stainless steel casting impellers so durable?

Stainless steel impellers are durable because of their ability to withstand extreme conditions, including high temperatures, corrosive chemicals, and mechanical stress.

How does corrosion resistance benefit stainless steel casting impellers?

Corrosion resistance ensures that stainless steel impellers can be used in wet or chemically harsh environments without degrading, which leads to less maintenance and increased reliability.

Can stainless steel casting impellers handle high pressure?

Yes, stainless steel impellers are designed to handle high-pressure applications due to their superior mechanical strength.

Why is wear resistance important for stainless steel casting impellers?

Wear resistance reduces the need for frequent replacements and ensures the impeller continues to perform efficiently even in abrasive environments.

In which industries are stainless steel casting impellers commonly used?

Stainless steel casting impellers are widely used in industries such as water treatment, pharmaceuticals, oil and gas, and food processing.

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF