Lieferanten von Ventilzubehör: 7 entscheidende Auswahlfaktoren

Willkommen auf meinem Blog!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

Inhaltsverzeichnis

Einführung

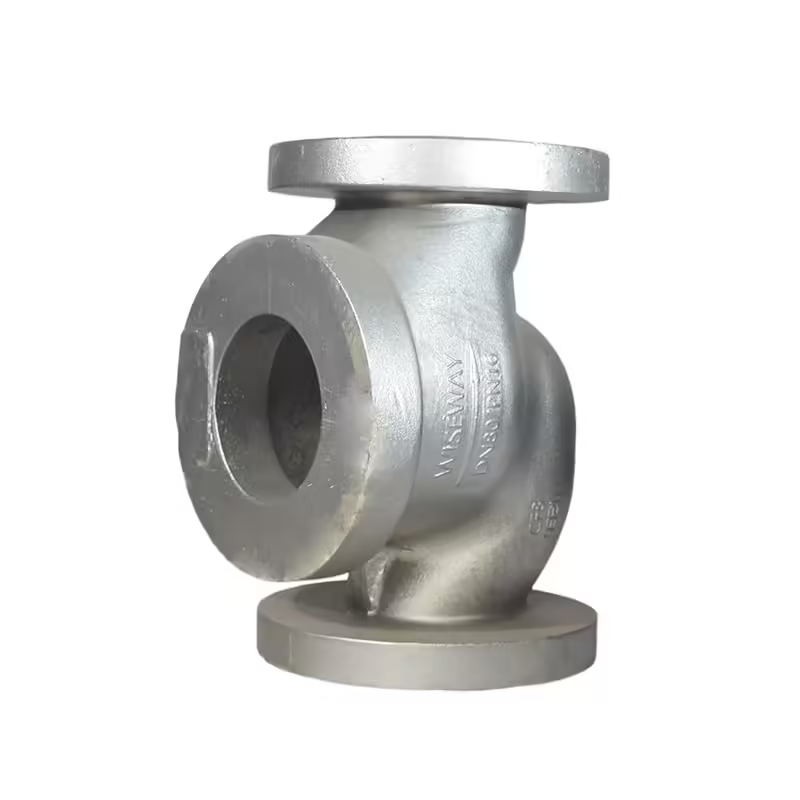

In today’s global industrial landscape, selecting the right valve accessories suppliers has become increasingly crucial for maintaining operational efficiency and system reliability. High-quality valve components form the backbone of fluid control systems across numerous industries including oil and gas, chemical processing, power generation, and water treatment facilities. The consequences of choosing substandard valve accessories can be severe – ranging from costly downtime to catastrophic system failures.

This comprehensive guide examines seven critical factors that discerning buyers must consider when evaluating valve accessories suppliers. We’ll explore technical specifications, quality assurance protocols, manufacturing capabilities, and value-added services that separate industry leaders from average providers. Additionally, we’ll highlight how Shanghai Leierwo Industry & Trade Co., Ltd. has established itself as a premier global supplier through its commitment to excellence in valve component manufacturing.

NO 1. Material Quality and Certification Standards: The Foundation of Reliability

Understanding Material Specifications

The performance and longevity of valve accessories begin with proper material selection. Reputable valve accessories suppliers must offer a comprehensive range of material options to meet diverse application requirements:

- Carbon Steels: Ideal for general service applications with moderate temperatures and pressures

- Alloy Steels: Provide enhanced strength for high-pressure systems

- Stainless Steels: Essential for corrosive environments and sanitary applications

- Duplex and Super Duplex Alloys: For extreme corrosion resistance

- Nickel-Based Alloys: Suitable for high-temperature services

Certification and Compliance

Leading valve accessories suppliers maintain rigorous certification programs to ensure material traceability and quality:

| Certification | Purpose | Importance |

|---|---|---|

| ISO 9001:2015 | Quality Management System | Ensures consistent manufacturing processes |

| IATF 16949:2016 | Automotive Quality Management | Demonstrates advanced process control |

| PED 2014/68/EU | Pressure Equipment Directive | Compliance for European markets |

| ASME B16.34 | Valve Standards | Ensures dimensional and performance compliance |

| NACE MR0175 | Sulfide Stress Cracking | Critical for oil and gas applications |

At Shanghai Leierwo, we go beyond basic certifications by implementing:

- Full material traceability from raw material to finished product

- Third-party laboratory testing for critical applications

- Comprehensive material test reports with each shipment

- Regular supplier audits to maintain material quality standards

NO 2. Manufacturing Capabilities and Technical Expertise

When evaluating valve accessories suppliers, their manufacturing capabilities directly determine product quality and performance. Leading valve accessories suppliers distinguish themselves through advanced production technologies that ensure precision and reliability across all components.

Core Manufacturing Technologies of Premier Valve Accessories Suppliers

- Precision Casting Solutions

- Investment casting (±0.3mm tolerance) for complex valve components

- Sand casting capabilities (up to 2000kg) for large valve bodies

- Shell molding processes for medium-volume valve accessory production

- Advanced Machining Capabilities

- 5-axis CNC machining centers for intricate valve trim components

- Multi-tasking turning centers for complete valve stem machining

- High-speed machining for superior surface finishes on sealing surfaces

- Specialized Finishing Processes

- Electrolytic polishing for corrosion-resistant valve interiors

- HVOF coating for enhanced wear resistance in high-cycle valves

- Passivation treatments for stainless steel valve accessories

Engineering Support from Elite Valve Accessories Suppliers

Top valve accessories suppliers provide comprehensive technical services:

- Design for Manufacturability (DFM) analysis for valve components

- Finite Element Analysis (FEA) for stress optimization in valve bodies

- Computational Fluid Dynamics (CFD) for flow efficiency in valve designs

- Rapid prototyping services for valve accessory development

Leierwo’s engineering team, a leader among valve accessories suppliers, includes:

- 15+ senior mechanical engineers specializing in valve technology

- ASME-certified welding specialists for pressure boundary joints

- Materials scientists focused on valve-grade alloys

- Quality professionals trained in API and ASME valve standards

NO 3. Quality Control and Testing Protocols

Reputable valve accessories suppliers implement rigorous quality control protocols to ensure every component meets stringent industry requirements.

Multi-Stage Quality Systems at Leading Valve Accessories Suppliers

- Material Verification

- Spectrochemical analysis of valve alloy compositions

- Mechanical testing of valve component prototypes

- Microstructure evaluation for critical valve applications

- Production Controls

- Dimensional verification at all valve manufacturing stages

- Comprehensive NDT (PT, MT, UT, RT) for valve integrity

- Statistical process control for valve production consistency

- Final Validation

- Complete dimensional inspection using CMM technology

- Functional testing of assembled valve accessories

- Surface finish analysis for optimal valve performance

Testing Equipment Comparison

| Test Type | Basic Supplier | Advanced Supplier | Leierwo Standard |

|---|---|---|---|

| Dimensional | Manual gauges | CMM (0.01mm) | CMM + Optical Comparator |

| Material | Basic spectrometer | Advanced OES | OES + SEM/EDS |

| Pressure | Hydrostatic | Hydro + Pneumatic | Full range testing |

| NDT | Visual only | PT/MT | PT/MT/UT/RT |

| Documentation | COA only | Full MTR | MTR + Test Videos |

NO 4. Customization and Value-Added Services

Engineering Support Capabilities

Leading valve accessories suppliers offer:

- Reverse engineering services

- Legacy component reproduction

- Application-specific material selection

- Performance optimization consulting

Leierwo’s Customization Process

- Design Consultation

- Application analysis

- Material selection

- Cost optimization

- Prototyping

- 3D printing options

- Rapid tooling

- Functional prototypes

- Testing and Validation

- Performance testing

- Life cycle analysis

- Field trial coordination

- Production Ramp-Up

- Pilot production

- Process validation

- Full-scale manufacturing

NO 5. Production Capacity and Supply Chain Management

Global Supply Chain Considerations

When evaluating valve accessories suppliers, examine:

- Raw material sourcing networks

- Secondary processing capabilities

- Inventory management systems

- Logistics partnerships

These factors also play a critical role in materials like 1020 steel, where the 1020 steel yield strength can be affected by the sourcing and treatment processes. Having a reliable supply chain ensures consistent quality and performance of materials, including carbon steels, which are commonly used in industrial applications.

Leierwo’s Manufacturing Advantages

- 80,000+ square meter production facility

- 200+ skilled technicians

- 5,000+ ton annual casting capacity

- Vertical integration from raw material to finished product

- Dedicated export department with 15+ years experience

NO 6. Industry-Specific Solutions

Application-Specific Expertise

Top valve accessories suppliers develop specialized knowledge for:

- Oil and Gas Applications

- API 6A/6D compliance

- Sour service capabilities

- High-pressure designs

- Power Generation

- High-temperature alloys

- Erosion-resistant designs

- Nuclear-grade materials

- Chemical Processing

- Corrosion-resistant materials

- Sealing technologies

- Zero-leakage designs

- Water Treatment

- Biofouling resistance

- Low-maintenance designs

- Drinking water compliance

NO 7. After-Sales Support and Continuous Improvement

Comprehensive Customer Support

Reliable valve accessories suppliers provide:

- Technical documentation

- Installation guidance

- Maintenance recommendations

- Spare parts management

Leierwo’s Commitment to Excellence

- 24/7 technical support

- Online order tracking

- Preventive maintenance programs

- Continuous product improvement initiatives

Warum wählen Shanghai Leierwo as Your Valve Accessories Supplier?

With nearly two decades of experience in precision metal manufacturing, Shanghai Leierwo Industry & Trade Co., Ltd. has established itself as a global leader in valve component production. Our comprehensive capabilities include:

Unmatched Technical Capabilities:

- ±0.3mm casting tolerances

- Ra 3.2μm surface finishes

- Full-spectrum material options

- Advanced non-destructive testing

Quality Assurance:

- ISO 9001:2015 certified

- IATF 16949:2016 compliant

- 12-stage inspection process

- 100% dimensional verification

Customer-Centric Services:

- 3-5 week standard lead times

- Free sample program

- Design optimization support

- Global logistics solutions

Our team of over 200 skilled professionals stands ready to assist with your most challenging valve accessory requirements. From prototype development to full-scale production, we combine technical expertise with practical manufacturing experience to deliver solutions that exceed expectations.

Abschluss

Selecting the optimal valve accessories supplier requires careful evaluation of technical capabilities, quality systems, and service offerings. By prioritizing suppliers with demonstrated expertise, robust quality controls, and customer-focused approaches, industrial buyers can secure reliable, high-performance components that deliver long-term value.

The seven factors outlined in this guide provide a comprehensive framework for supplier evaluation. Organizations that methodically assess potential partners against these criteria will be well-positioned to establish productive, long-term relationships with valve accessories suppliers capable of meeting their most demanding requirements.

Häufig gestellte Fragen

Q: What minimum order quantities does Leierwo typically require?

A: We accommodate orders ranging from prototype quantities (1-10 pieces) to full production runs (10,000+ pieces), with flexible options to meet your specific needs.

Q: How does Leierwo handle intellectual property protection?

A: We implement strict confidentiality agreements, secure data management systems, and controlled access protocols to protect customer designs and proprietary information.

Q: What file formats do you accept for custom designs?

A: Our engineering team can work with all major CAD formats including STEP, IGES, Parasolid, and native SolidWorks/Inventor files.

Q: What shipping methods are available for international orders?

A: We offer multiple logistics options including air freight, sea freight, and expedited courier services, with comprehensive export documentation.

Q: How does Leierwo support customers with urgent requirements?

A: Our rapid response team can expedite production for critical needs, with options for partial shipments and priority manufacturing scheduling.

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF