5 Key Differences: Hastelloy vs Stainless Steel – Which Wins?

Welcome to My Blog!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

Table of Contents

Introduction

The selection of materials for industrial applications often comes down to a critical comparison between Hastelloy vs Stainless Steel. Both alloys are widely recognized for their corrosion resistance and mechanical properties, but they serve distinctly different purposes depending on the operational environment. Understanding the fundamental differences in Hastelloy vs Stainless Steel is essential for engineers, designers, and procurement specialists who need to optimize performance while controlling costs.

This comprehensive analysis will explore five key areas where Hastelloy vs Stainless Steel differ significantly: chemical composition, corrosion resistance, temperature performance, mechanical properties, and cost considerations. By examining these factors in detail, we aim to provide clarity on which material—Hastelloy vs Stainless Steel—is better suited for specific applications, helping readers make informed decisions for their projects.

For instance, when evaluating Hastelloy vs Stainless Steel, the former excels in highly corrosive environments, while the latter offers cost-effective solutions for moderate conditions. The debate of Hastelloy vs Stainless Steel ultimately hinges on balancing performance requirements with budget constraints.

NO 1. Composition: The Fundamental Building Blocks

Hastelloy‘s Advanced Alloy Structure

Hastelloy represents a family of nickel-based superalloys that incorporate substantial amounts of molybdenum and chromium, with some grades including tungsten and cobalt. The primary hastelloy variants, such as C-276, C-22, and B-2, are engineered specifically to withstand some of the most aggressive chemical environments encountered in industrial processing. The high nickel content (typically 45-65%) provides exceptional resistance to reducing agents, while molybdenum (15-17%) enhances protection against localized corrosion mechanisms like pitting and crevice corrosion.

Stainless Steel’s Iron-Based Foundation

In contrast, stainless steel is fundamentally an iron-based alloy where chromium (minimum 10.5%) provides the primary corrosion resistance through the formation of a passive oxide layer. The most common grades, 304 and 316 stainless steel, incorporate nickel (8-11%) to improve formability and molybdenum (2-3% in 316) for enhanced chloride resistance. While these compositions offer excellent performance in many environments, they lack the specialized elemental additions that give hastelloy its superior performance in extreme conditions.

The compositional differences between hastelloy vs stainless steel directly influence their microstructure, phase stability, and ultimately their performance characteristics in real-world applications. Engineers must consider these variances when selecting between hastelloy vs stainless steel for specific projects.

NO 2. Corrosion Resistance: Performance in Aggressive Environments

Hastelloy’s Unmatched Chemical Resistance

When evaluating hastelloy vs stainless steel for corrosion resistance, hastelloy demonstrates clear superiority in highly aggressive chemical environments. The alloy’s resistance to both oxidizing and reducing acids, including sulfuric, hydrochloric, and phosphoric acids, makes it indispensable in chemical processing equipment. Hastelloy C-276, for example, maintains excellent corrosion rates even in boiling hydrochloric acid solutions where stainless steel would fail catastrophically within hours.

The material’s performance extends to resistance against stress corrosion cracking in chloride-bearing environments, a common failure mode for stainless steels in marine and offshore applications. Hastelloy’s immunity to chloride-induced cracking at temperatures up to 150°C (302°F) makes it particularly valuable in heat exchanger tubes and reactor vessels.

Stainless Steel’s Limitations in Harsh Conditions

While stainless steels perform admirably in many industrial and consumer applications, their corrosion resistance has well-defined boundaries. Grade 316 stainless steel offers improved performance over 304 in chloride environments, but both will experience pitting and crevice corrosion when exposed to high chloride concentrations, especially at elevated temperatures.

In acidic environments, stainless steels are generally limited to very dilute concentrations at moderate temperatures. For instance, 316 stainless steel can handle sulfuric acid at concentrations below 10% at room temperature, but performance degrades rapidly with increasing concentration and temperature. This makes stainless steel unsuitable for many chemical processing applications where hastelloy thrives.

NO 3. Temperature Performance: Maintaining Integrity Under Heat

Hastelloy’s High-Temperature Capabilities

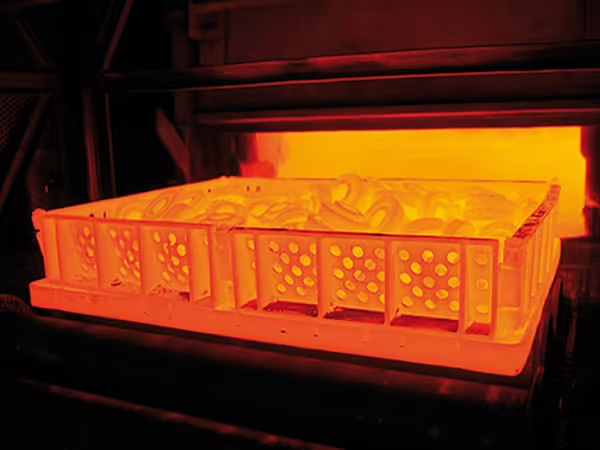

The comparison of hastelloy vs stainless steel becomes particularly pronounced when examining high-temperature performance. Hastelloy alloys maintain excellent mechanical properties and oxidation resistance at temperatures exceeding 1000°C (1832°F) in many cases. The nickel-based matrix provides exceptional creep resistance, making these alloys ideal for gas turbine components, furnace hardware, and pyrolysis units.

Hastelloy X, a specific variant designed for extreme temperature service, combines oxidation resistance with high strength up to 1200°C (2192°F). This makes it valuable in aerospace applications such as combustion chambers and afterburner components where materials must withstand both mechanical stress and thermal cycling.

Stainless Steel’s Thermal Limitations

Stainless steels exhibit good oxidation resistance up to about 800°C (1472°F), but their mechanical properties degrade significantly above this threshold. The iron-based matrix becomes susceptible to excessive creep deformation, and prolonged exposure can lead to sensitization issues in some grades.

High-temperature stainless steels like 310S offer improved performance with higher chromium and nickel contents, but they still cannot match the temperature capabilities of nickel-based superalloys like hastelloy. In applications involving cyclic thermal loading, stainless steels are more prone to thermal fatigue cracking compared to hastelloy alloys.

NO 4. Mechanical Properties: Strength and Fabrication Considerations

Hastelloy’s Strength Characteristics

When comparing the mechanical properties of hastelloy vs stainless steel, hastelloy generally offers higher tensile and yield strength, particularly at elevated temperatures. Typical room temperature tensile strength for hastelloy C-276 is approximately 790 MPa (115 ksi), compared to about 515 MPa (75 ksi) for 316 stainless steel.

The nickel-based structure provides excellent toughness and ductility even at cryogenic temperatures, making hastelloy suitable for liquefied gas handling equipment. However, the material’s high work hardening rate can present challenges during machining and forming operations, often requiring specialized tooling and techniques.

Stainless Steel’s Fabrication Advantages

Stainless steels are generally easier to machine, form, and weld compared to hastelloy alloys. The lower work hardening rate and better thermal conductivity of stainless steel make it more forgiving during fabrication processes. This translates to lower manufacturing costs and broader availability of prefabricated components.

The austenitic structure of 300-series stainless steels provides excellent ductility and formability, allowing for complex shapes to be produced through deep drawing and other forming operations. While some hastelloy grades can be formed, they typically require more force and are more prone to springback.

NO 5. Cost Analysis: Balancing Performance and Budget

Hastelloy’s Premium Pricing Structure

The superior performance of hastelloy comes at a significant cost premium. The high nickel and molybdenum content, combined with more complex manufacturing processes, results in material costs that are typically 5-10 times higher than standard stainless steels. This makes hastelloy a selective choice reserved for applications where its unique properties are absolutely necessary.

Stainless Steel’s Economic Advantages

Stainless steel offers an excellent balance of performance and cost for a wide range of applications. The abundance of iron and relatively lower alloying element content keeps material costs reasonable, while still providing good corrosion resistance and mechanical properties. For many industrial and consumer applications, stainless steel represents the most cost-effective solution.

Cost and Performance Comparison Table

| Material Property | Hastelloy C-276 | 316 Stainless Steel |

|---|---|---|

| Nickel Content | 57% | 10-13% |

| Molybdenum Content | 15-17% | 2-3% |

| Tensile Strength (MPa) | 790 | 515 |

| Maximum Service Temp (°C) | 1093 | 800 |

| Cost per kg (USD) | 50-100 | 5-15 |

| Best Applications | Chemical processing, aerospace | Marine, medical, food processing |

Conclusion

The decision between hastelloy vs stainless steel ultimately depends on the specific requirements of the application. Hastelloy vs stainless steel reveals that hastelloy excels in extreme environments with superior corrosion resistance and high-temperature performance, making it indispensable for chemical processing, aerospace, and energy sectors. However, the higher cost and more complex fabrication process of hastelloy limit its use to applications where its unique properties are absolutely essential.

In contrast, hastelloy vs stainless steel shows that stainless steel is the material of choice for most industrial and consumer applications, where good corrosion resistance and mechanical properties are required at a more reasonable cost. Its easier fabrication and widespread availability make stainless steel the practical solution for everything from architecture to food processing.

By carefully evaluating the differences in hastelloy vs stainless steel—such as composition, corrosion resistance, temperature performance, mechanical properties, and cost—engineers and designers can make informed decisions to optimize both performance and budget for their specific applications.

FAQ

Can stainless steel be used instead of hastelloy in chemical processing?

Stainless steel may be used in mild chemical environments, but it cannot match hastelloy vs stainless steel performance in concentrated acids or high-temperature corrosive conditions. In such applications, hastelloy proves to be far superior.

What makes hastelloy more resistant to chlorides than stainless steel?

The combination of high nickel and molybdenum content in hastelloy vs stainless steel makes hastelloy more resistant to chloride-induced pitting and stress corrosion cracking that commonly affects stainless steel in chloride environments.

Is hastelloy suitable for structural applications?

While hastelloy has excellent mechanical properties, its high cost typically limits structural use to specialized applications where corrosion resistance is critical.

How does the welding of hastelloy compare to stainless steel?

Hastelloy requires more stringent welding procedures, often needing post-weld heat treatment and specialized filler metals to maintain corrosion resistance.

Are there any environmental advantages to using hastelloy over stainless steel?

Hastelloy vs stainless steel comparison shows that hastelloy’s extreme durability can lead to a longer service life in harsh environments, potentially reducing material consumption over time despite its higher initial environmental impact.

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF