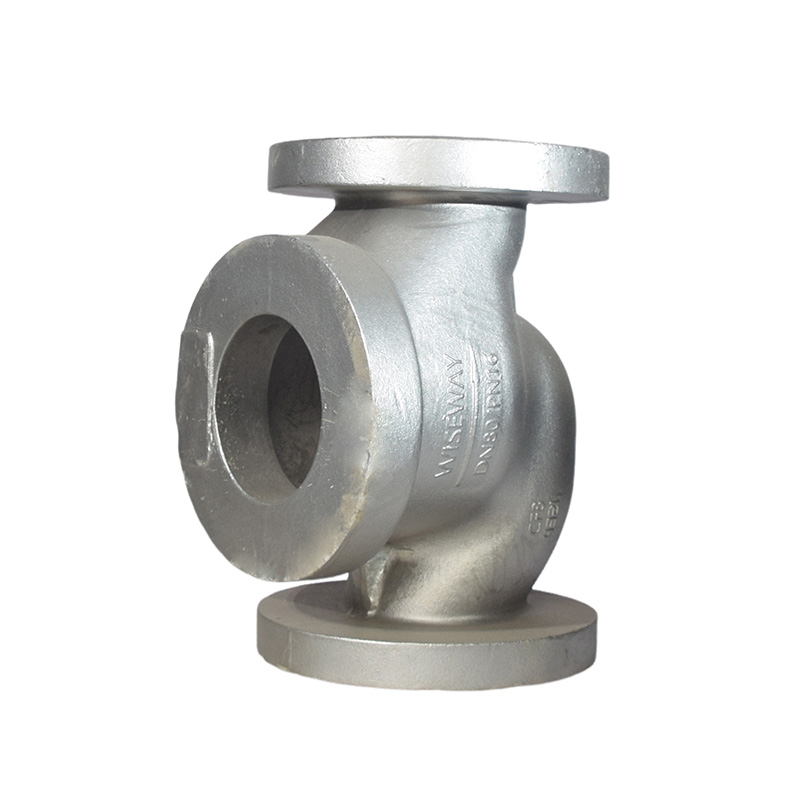

Stainless Steel Castings

Stainless steel casting is a manufacturing process that involves pouring molten stainless steel into a mold to create custom stainless steel components. We specialize in producing high-quality stainless steel castings for a wide range of industries, including construction machinery, marine, oil and gas, automotive, and other heavy equipment sectors.

Our capabilities include stainless steel investment casting and stainless steel sand casting, offering the flexibility to produce stainless steel castings that meet diverse design and performance requirements. With advanced techniques and strict quality control, we ensure that each stainless steel casting delivers precision, durability, and excellent corrosion resistance.

Whether you need complex, intricate parts or large, heavy-duty components, our stainless steel castings are tailored to meet your specific needs, providing reliable solutions for demanding applications.

Our capabilities include stainless steel investment casting and stainless steel sand casting, offering the flexibility to produce stainless steel castings that meet diverse design and performance requirements. With advanced techniques and strict quality control, we ensure that each stainless steel casting delivers precision, durability, and excellent corrosion resistance.

Whether you need complex, intricate parts or large, heavy-duty components, our stainless steel castings are tailored to meet your specific needs, providing reliable solutions for demanding applications.

Common Material Grades of Stainless Steel Castings

| ALLOY CLASS | ALLOY NAME | MECHANICAL PROPERTIES | MATERIAL CHARACTERISTICS | APPLICATION INDUSTRY | EXAMPLE PART |

|---|---|---|---|---|---|

| Austenitic | 304 stainless steel | Tensile Strength: 515-690 MPa Hardness: 70-92 HRB |

Corrosion resistance (high nickel) Ductility (low carbon content) Widely used |

Food Processing, Kitchen | Kitchen sinks, Process equipment (e.g., tanks) |

| Austenitic | 304L stainless steel | Tensile Strength: 485-655 MPa Hardness: 70-88 HRB |

Lower carbon for weldability Improved ductility |

Chemical, Oil & Gas | Process equipment, Heat exchangers |

| Austenitic | 316 stainless steel | Tensile Strength: 515-690 MPa Hardness: 75-95 HRB |

Molybdenum-enhanced corrosion resistance | Paper industry, Chemical processing, Pharmaceutical | Propellers, Medical devices, Furnace parts |

| Austenitic | 316L stainless steel | Tensile Strength: 485-655 MPa Hardness: 75-95 HRB |

Optimized weldability Enhanced corrosion resistance |

Marine, Chemical | Marine components, Chemical vessels |

| Austenitic | 201 stainless steel | Tensile Strength: 620-795 MPa Hardness: 70-88 HRB |

Cost-effective (reduced nickel content) | Construction, Automotive | Structural components, Springs |

| Duplex | 2205 stainless steel | Tensile Strength: 620-800 MPa Hardness: 20-35 HRC |

Dual-phase structure Stress/corrosion resistance |

Oil & Gas, Chemical | Pipes, Pressure vessels |

| Martensitic | 410 stainless steel | Tensile Strength: 450-655 MPa Hardness: 70-85 HRB |

Heat-treatable Machinability |

Aerospace, Firearms | Aircraft components, Bolts, Mechanical parts |

| PH | 17-4PH stainless steel | Tensile Strength: 725-930 MPa Hardness: 30-45 HRC |

Precipitation-hardened High strength-to-weight ratio |

Aerospace, Medical | Aircraft landing gear, Surgical instruments |

Stainless Steel Casting Process

Stainless Steel Investment Casting

By fully adopting advanced silica sol shell-making technology, we have significantly improved the accuracy, surface finish, and overall performance of our stainless steel castings. Additionally, we have introduced a shell-making process combined with coated sand to further optimize production efficiency and ensure the highest quality standards. This process allows us to produce stainless steel castings with intricate designs and exceptional precision, making them ideal for demanding industrial applications.

Stainless Steel Sand Casting

In the sand casting process, we select sand mold materials, such as resin sand and ceramsite sand, based on customer performance requirements. Ceramsite sand, known for its uniform particles and excellent refractory properties, is particularly suitable for high-temperature and challenging casting applications. We strictly follow post-inspection and recycling processes to ensure the quality of the sand molds and the stainless steel castings produced. Our goal is to consistently meet customer demands for high-quality and reliable stainless steel castings.

Stainless Steel Shell Mold Casting

Our shell mold casting production line is equipped with the latest imported machinery, including eight automated units capable of manufacturing stainless steel castings weighing up to 200 kg. With a monthly production capacity of 800 tons, our experienced team ensures both efficient production and rigorous quality inspection. This allows us to deliver stainless steel castings that meet the highest standards of precision, durability, and performance for a wide range of industrial applications.

One-Stop Solution

Heat Treatment

Heat treatment is a process that alters the properties of metals or alloys by controlling heating and cooling. This enhances hardness, strength, and corrosion resistance, ensuring that stainless steel castings meet the required performance standards. Our primary methods include normalizing, annealing, and tempering, tailored to optimize the mechanical properties of stainless steel castings for various industrial applications.

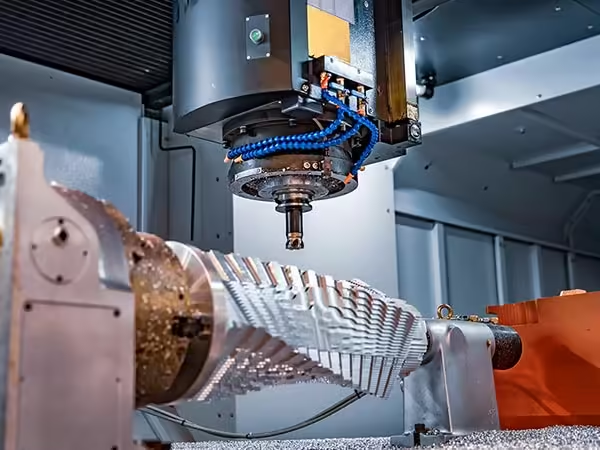

Post-Machining

Although stainless steel precision castings can achieve high dimensional accuracy and surface finish, some applications require additional machining to meet strict tolerance and surface finish requirements. Our professional machining services enable us to manufacture stainless steel castings with complex geometries and intricate details while maintaining high precision and accuracy. Equipped with a full range of machining equipment, from manual turning and milling to advanced CNC machining services, we ensure that every stainless steel casting meets exact specifications.

Surface Treatment

To enhance the performance and appearance of stainless steel castings, we apply various surface treatment methods, including rust-proof oil coating, painting, sandblasting, chemical treatment, anodizing, and electrophoresis. These treatments improve corrosion resistance, enhance wear resistance, and provide a polished finish, ensuring that our stainless steel castings deliver both durability and aesthetic appeal.

Start Your Project with Leierwo

1. Submit Your Inquiry

Send your CAD drawings and 3D files via email, specifying material grade, order quantity, surface finish, or any other relevant details.

2. Cost Calculation

Once we receive your design, our engineering team will carefully evaluate the drawings and calculate the price based on actual production costs as soon as possible.

3. Start Production

Upon pricing approval, our production team will prepare the materials and schedule production promptly.Leierwo always ensures on-time delivery.

4. Arrange Delivery

After production is completed, we will provide packaging details and arrange shipment via sea or air. We support global shipping for every order.

FAQ

Do you offer export services?

Why choose leierwo foundry for stainless steel casting?

What is your production capacity? Do you accept custom orders?

What international standards do your stainless steel castings comply with?

How do you ensure product quality?

What is your Minimum Order Quantity (MOQ)?

What is your lead time?

Can you provide samples?