Pump Manufacturing

Product Information Download

In order to help global customers better understand our products, we are committed to providing you with detailed product information to help you choose the products that meet your needs.

Advantages

Pump products typically require high casting precision and material properties, and Leierwo’s expertise in pump casting is particularly prominent. The company’s extensive application in pump and valve accessories demonstrates its mastery of the casting process for key components such as pump bodies, impellers, and sleeves. Precision casting technology effectively controls the uniformity of casting wall thickness and internal cavity accuracy, reducing subsequent processing and improving overall efficiency. Furthermore, the company can recommend the most appropriate casting process based on component structure to further optimize the performance of pump products and meet the corrosion resistance, heat resistance, and fluid dynamics requirements of various industries.

View Our Products

Main Material Selection

In Pump Manufacturing, castings are exposed to liquid media for extended periods and often face challenges such as corrosion, wear, and cavitation. Therefore, materials must possess high corrosion and wear resistance, along with excellent casting properties to ensure long-term reliability and efficiency.

Common Materials Used in Pump Manufacturing

Stainless Steel Series:

316/316L: Preferred for pump casings, impellers, and shafts, resistant to acids, alkalis, and chloride ion corrosion.

2205 Duplex Steel: High strength and excellent pitting resistance, suitable for seawater pumps and chemical pumps.

304/304L: General-purpose pump components for water treatment and food industry pumps.

Carbon Steel Series:

1045: Suitable for pump shafts and casings in non-corrosive environments.

4130: Ideal for high-temperature, high-pressure pump structural components.

Special Alloy Series:

C95400 Bronze: Perfect for seawater pump sleeves and sliding components, offering excellent wear resistance and self-lubrication.

Cobalt Alloys (e.g., Co6): Used in impellers or sealing surfaces for high-wear, high-temperature pumps.

Common Materials Used in Pump Manufacturing

Stainless Steel Series:

316/316L: Preferred for pump casings, impellers, and shafts, resistant to acids, alkalis, and chloride ion corrosion.

2205 Duplex Steel: High strength and excellent pitting resistance, suitable for seawater pumps and chemical pumps.

304/304L: General-purpose pump components for water treatment and food industry pumps.

Carbon Steel Series:

1045: Suitable for pump shafts and casings in non-corrosive environments.

4130: Ideal for high-temperature, high-pressure pump structural components.

Special Alloy Series:

C95400 Bronze: Perfect for seawater pump sleeves and sliding components, offering excellent wear resistance and self-lubrication.

Cobalt Alloys (e.g., Co6): Used in impellers or sealing surfaces for high-wear, high-temperature pumps.

Key Casting Service Options in Pump Manufacturing

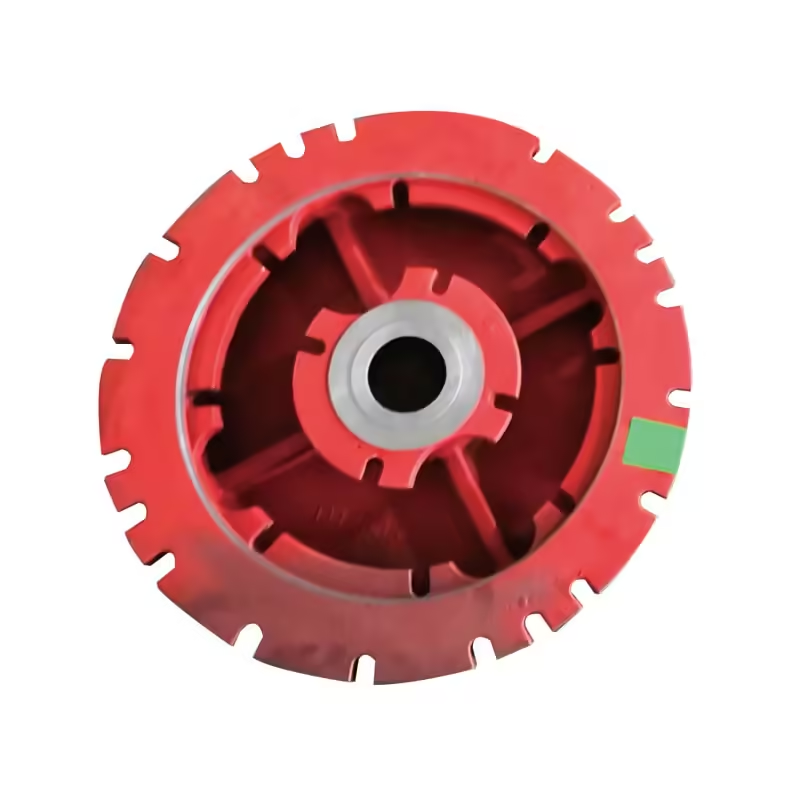

The fluid dynamics performance of pump components, such as impellers and pump bodies, depends on precise casting. Each Pump Manufacturing process targets specific component requirements:

Investment Casting: Ideal for complex flow path components. The impeller, as the heart of the pump, requires precise blade curves to meet fluid dynamics design. Investment casting achieves blade profile accuracy of ±0.1mm and a surface finish of Ra3.2µm or better, reducing fluid resistance and improving efficiency.

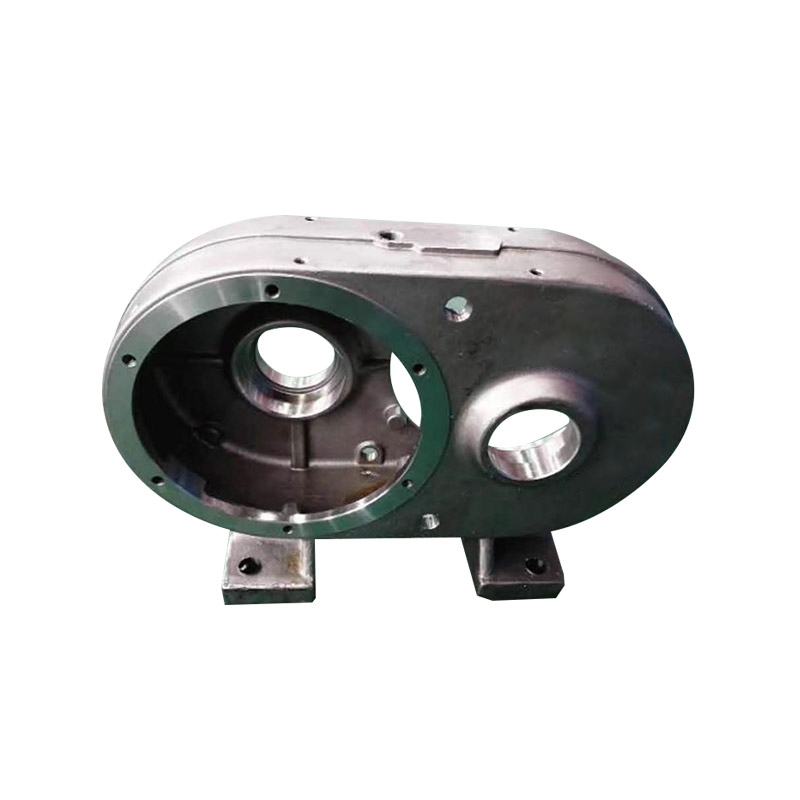

Sand Casting: Used for fundamental components like pump bodies. Pump bodies are typically cylindrical or square; sand casting supports mass production with low cost, short cycle times, and meets structural and fluid flow requirements.

CNC Machining: Ensures transmission and sealing accuracy. The connection between pump shaft and impeller, as well as the sealing surface between pump body and end cover, requires CNC machining for concentricity ≤0.01mm and precise flatness, preventing vibration and leakage during operation.

Investment Casting: Ideal for complex flow path components. The impeller, as the heart of the pump, requires precise blade curves to meet fluid dynamics design. Investment casting achieves blade profile accuracy of ±0.1mm and a surface finish of Ra3.2µm or better, reducing fluid resistance and improving efficiency.

Sand Casting: Used for fundamental components like pump bodies. Pump bodies are typically cylindrical or square; sand casting supports mass production with low cost, short cycle times, and meets structural and fluid flow requirements.

CNC Machining: Ensures transmission and sealing accuracy. The connection between pump shaft and impeller, as well as the sealing surface between pump body and end cover, requires CNC machining for concentricity ≤0.01mm and precise flatness, preventing vibration and leakage during operation.

What We Offer

Leierwo is committed to providing the highest quality precision metal parts manufacturing services, including precision casting, investment casting, sand casting, and CNC machining. We offer customized solutions and can complete your design within 3–5 weeks, depending on the complexity of the parts. Before mass production, we provide one free sample for testing and approval.

Investment Casting Service

Features: Investment casting has high precision, can adapt to complex shapes, has smooth surface and little material waste.

Applications: aerospace, precision machinery, automobiles, medical equipment, etc.

Sand Casting Service

Features: It uses sand mold, which is low in cost and suitable for large and complex-shaped metal castings.

Applications: automotive parts, mechanical structural parts, large castings.

Our Casting Services – Fufilled Across Metal Grades

Leierwo possesses extensive expertise across a wide range of alloy grades, enabling our customers to select the ideal materials to optimize their products and meet the most demanding global application requirements. Feel free to explore the alloy series listed below to find the perfect match for your specific needs.

We Provide Comprehensive Manufacturing Solutions

Investment Casting

Sand Casting

3D Printing

Stainless Steel Castings

Carbon Steel Castings

Alloy Steel Castings

Start Your Project with Leierwo

1. Submit Your Inquiry

Send your CAD drawings and 3D files via email, specifying material grade, order quantity, surface finish, or any other relevant details.

2. Cost Calculation

Once we receive your design, our engineering team will carefully evaluate the drawings and calculate the price based on actual production costs as soon as possible.

3. Start Production

Upon pricing approval, our production team will prepare the materials and schedule production promptly.Leierwo always ensures on-time delivery.

4. Arrange Delivery

After production is completed, we will provide packaging details and arrange shipment via sea or air. We support global shipping for every order.

FAQ

Q1. Are you a trading company or a manufacturer?

Q2. Can you quote based on 3D drawings?

Q3. How do you handle RFQs (Request for Quotation)?

Q4. What is your typical lead time?

Q5. Do you provide samples? Are they free?

Q6. What payment methods do you accept?

Q7. How do you ensure quality control?

Q8. Do your products come with a warranty?

Q9. How do you view your relationship with customers?